DVM Industries specializes in auditing and retrofitting existing motors both interval and fractional motors to EC (Electronically Commutated) We offer fully programmed EC Motors to save energy costs related to:

- Fan Powered Boxes

- Fan Coil Units

- Dry Coolers

- RTU’s (Rooftop Packaged Units)

- Exhaust Fans

- CRAC Units (Computer Room A/C)

Our technicians are highly trained on motor programming, installation and specification.

The Benefits

-

01 30 – 80% More Efficient

High Energy Energy Savings- Payback 1-3 Years.

-

02 Less Noise

Motors run extremely quiet, typically 70% less than your standard motor.

-

03 Extends the life of the motor.

Due to high efficiencies, less heat is generated, reducing stress on the windings and bearings which extends the life of the motor.

-

04 Less wear and tear

Soft ramp up and ramp down in speed results in less wear and tear of the equipment.

-

05 Recondition vs Replace

Recondition vs Replace: Cleaning system and replacing the motor to an EC motor not only saves substantial energy but is much more cost effective vs replacing the entire unit.

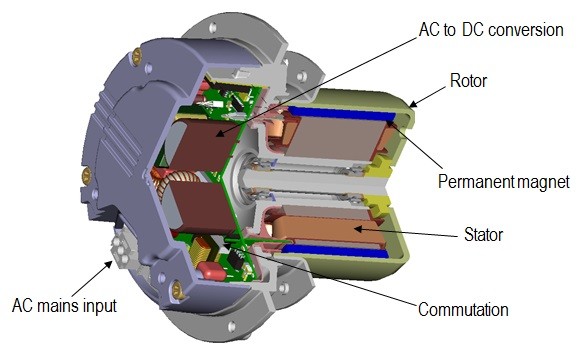

Why EC Motors

EC Technology stands for Electronically Commutated and combines AC and DC voltages, which is essentially a fan with a brushless DC motor, bringing the best of both technologies: the motor runs on a DC voltage, but with a normal AC supply. The EC motor incorporates voltage transformation within the motor. The nonrotating part of the motor (stator) is extended to make room for an electronic PCB (Printed Circuit) board which includes power transformation AC to DC, as well as the controls.

- EC motors can be retrofitted to replace existing AC motor components

- High Efficiency Variable Speed Motor

- Permanent magnet motor and electronic control allows for higher efficiencies and higher energy savings

- Similar to an interval horsepower motor with a VFD (Variable Frequency Drive)

- As speed is reduced the savings is to the cubed root.